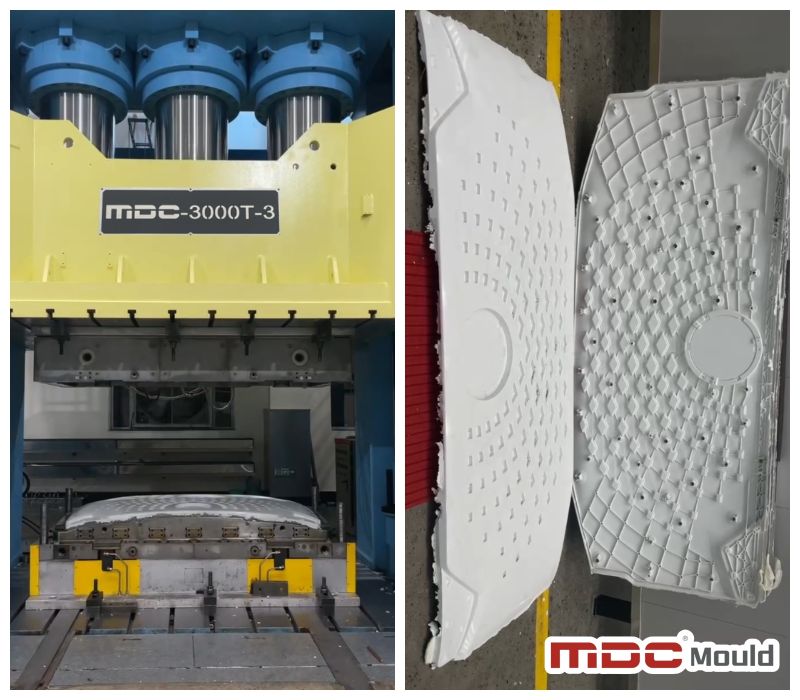

The SMC tool plays a critical role in the manufacturing of advanced thermoset composite components. Specifically designed for use in the Sheet Molding Compound (SMC) process, these high-precision tools—also known as SMC molds or SMC tooling—enable mass production of lightweight, durable, and complex-shaped parts used across automotive, electrical, and industrial sectors.

What Is an SMC Tool?

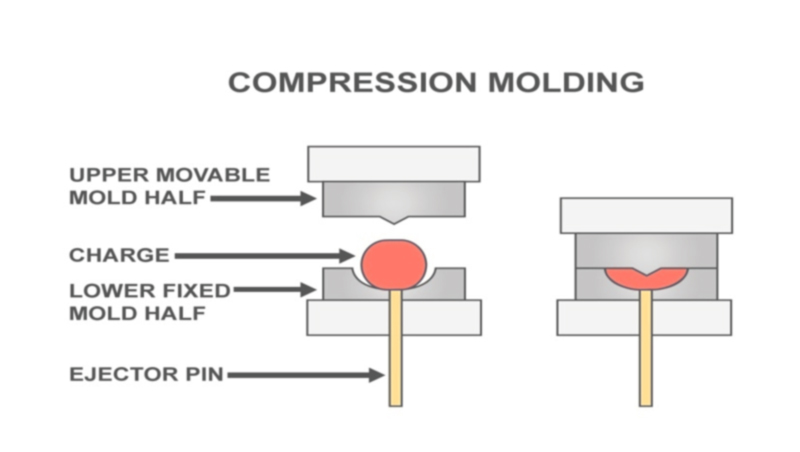

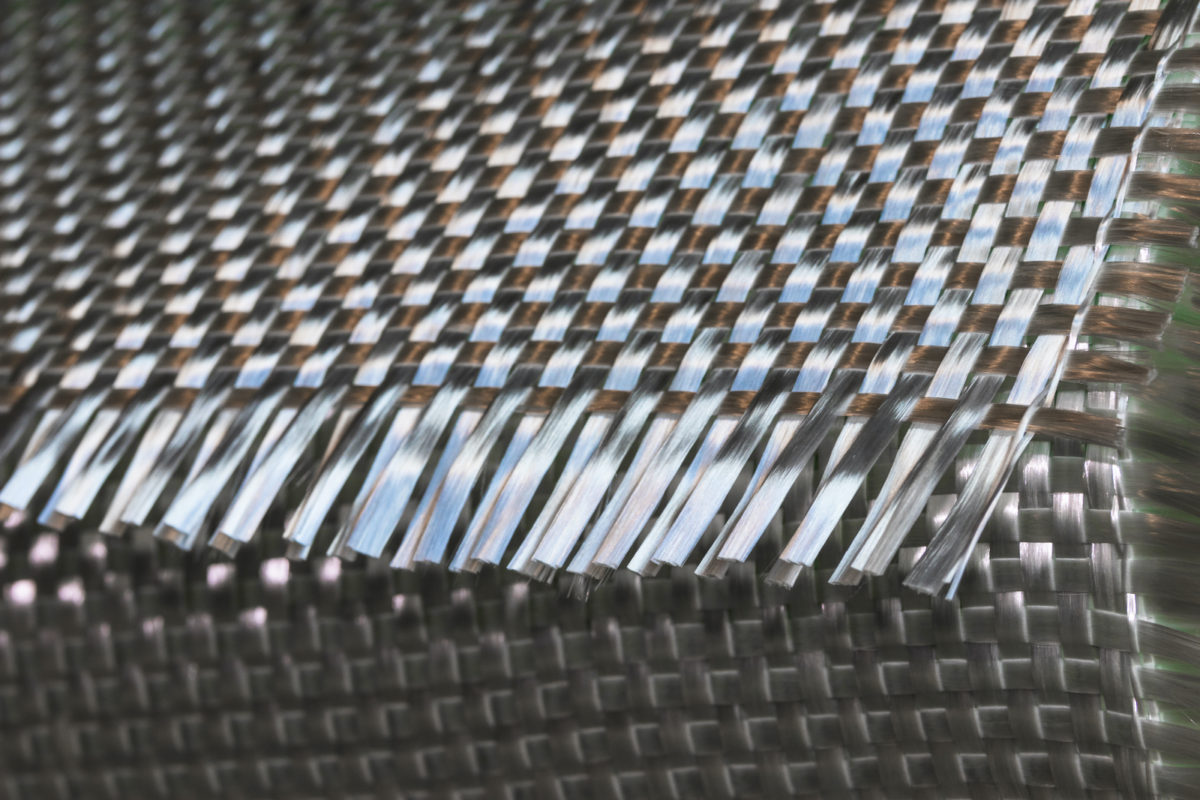

An SMC tool is a custom-designed mold used in the compression molding process of fiber-reinforced thermoset materials, primarily SMC. These tools are engineered to form and cure a pre-cut charge of SMC material into a finished component under high pressure and temperature. The precision of the tooling directly affects the surface finish, dimensional accuracy, and mechanical performance of the final part.

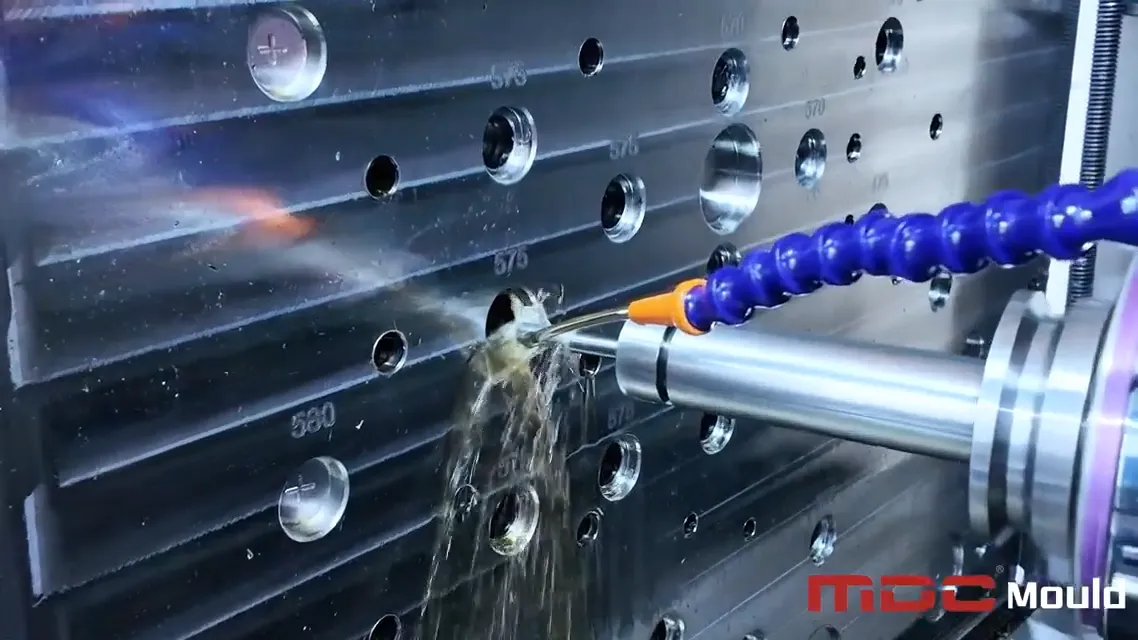

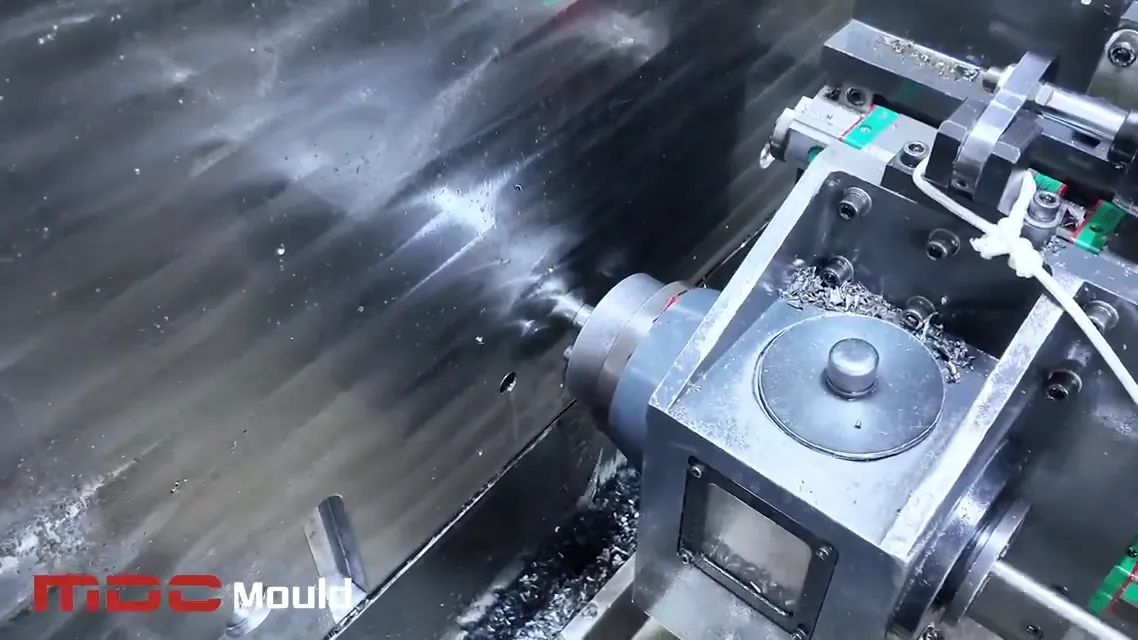

Materials and Construction of SMC Molds

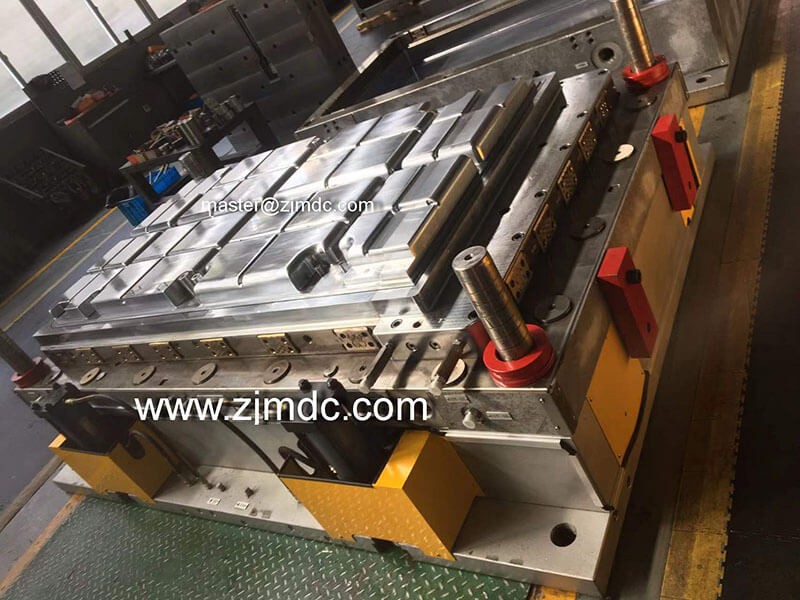

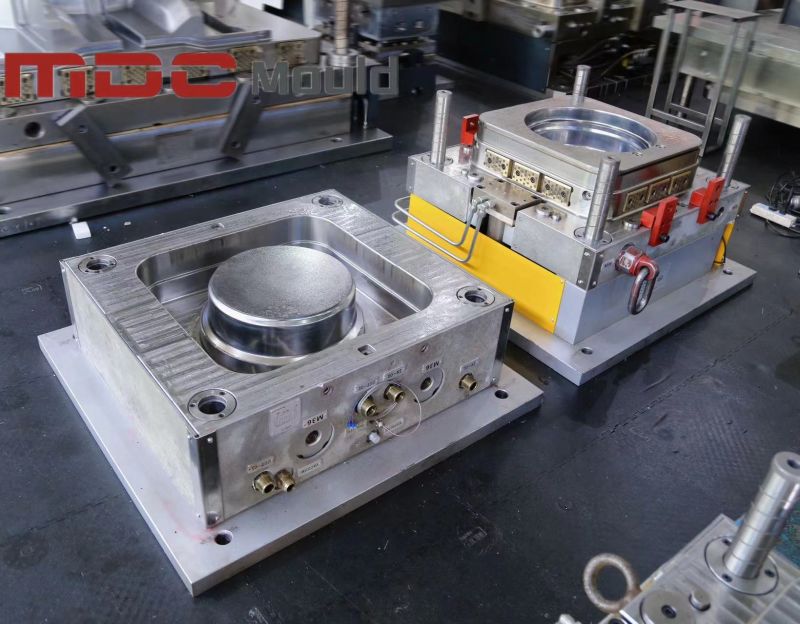

SMC tools are typically constructed from high-grade tool steel or aluminum, depending on the application and production volume. Common features of an SMC mold include:

- Core and Cavity: Precisely machined surfaces that define the shape of the part.

- Heated Platens: Used to maintain molding temperatures typically between 130°C and 160°C.

- Ejection System: Ejector pins or air ejectors facilitate smooth part removal after curing.

- Vacuum System: Removes trapped air to prevent voids and improve surface finish.

- Cooling Channels: Allow for cycle time optimization and dimensional stability.

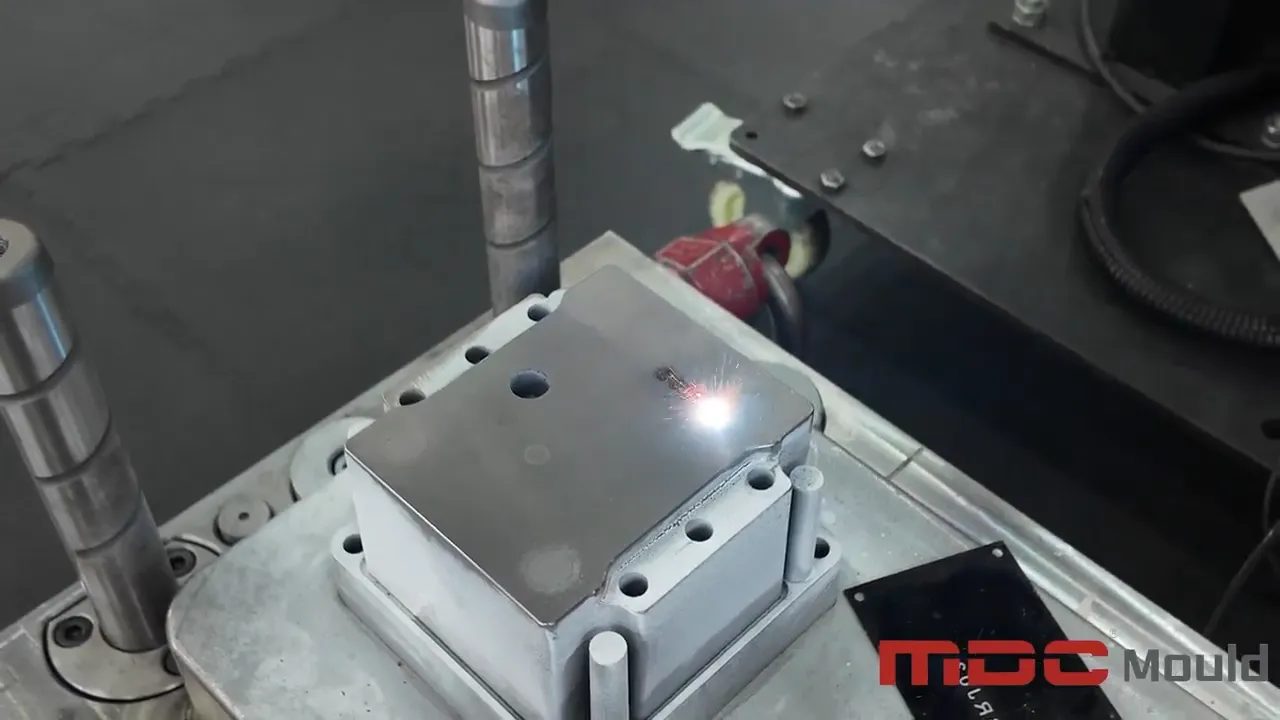

Advanced SMC tooling may also integrate surface textures, inserts, or multi-cavity configurations for high-volume production.

Applications of SMC Tooling

SMC tools are widely used across several industries that demand high-performance composite parts:

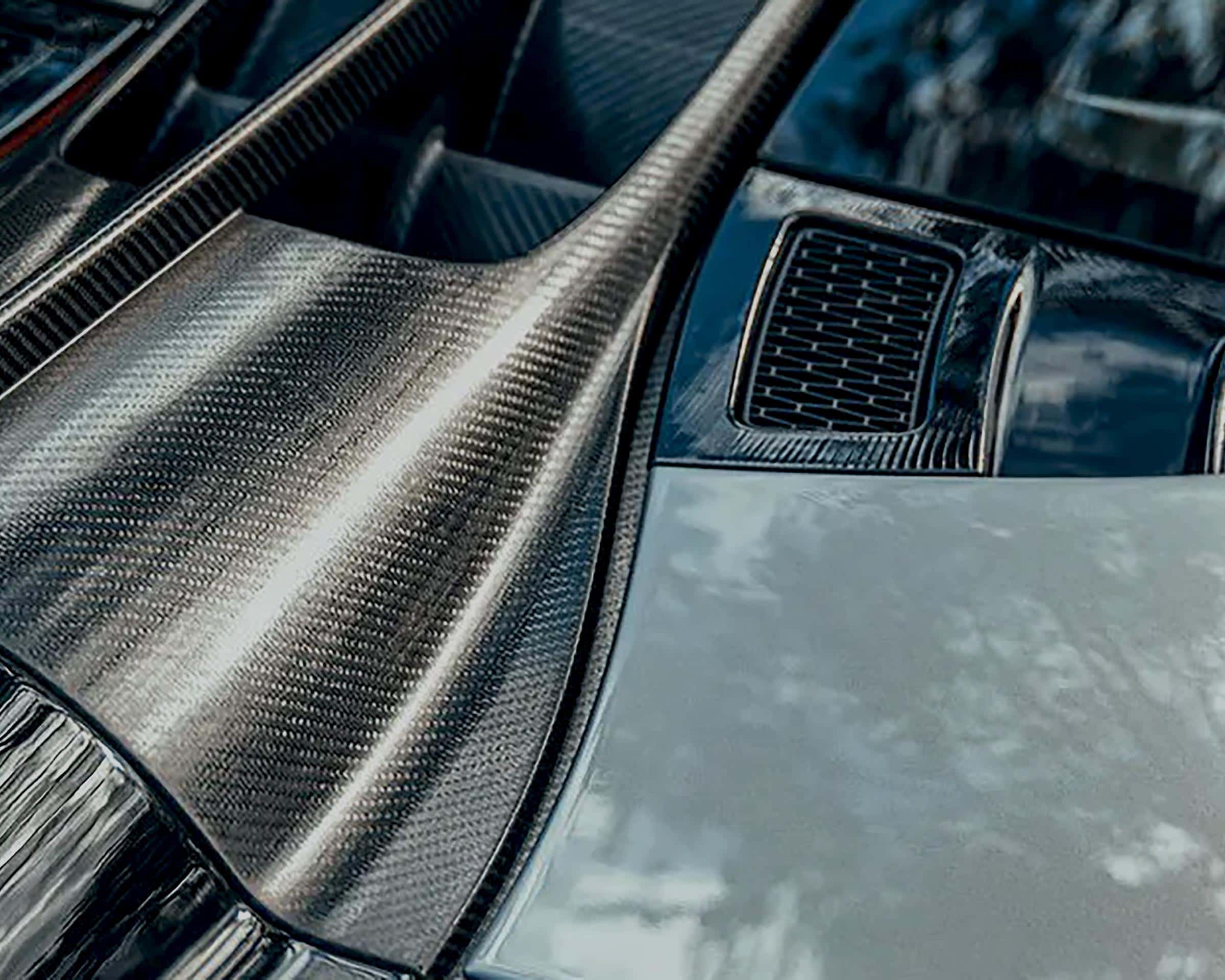

- Automotive: Battery enclosures, inner roofs, trunk boards, spoilers, and structural reinforcements.

- Electrical: Cable trays, switchgear panels, insulation covers, junction boxes.

- Sanitary: Bathtubs, shower trays, SMC bathrooms, and ceiling panels.

- Water Storage: SMC water tanks and sectional panel molds.

- Infrastructure: Manhole covers, gratings, and architectural components.

Advantages of Using SMC Tools

High-quality SMC tooling offers a variety of benefits for manufacturers:

- High Repeatability: Allows for consistent part production with tight tolerances.

- Fast Cycle Times: Optimized mold design ensures shorter curing durations and increased output.

- Surface Finish Control: Tools can be polished or textured to meet Class A surface requirements.

- Complex Geometry: Supports undercuts, ribs, and inserts for functional part integration.

- Durability: Steel tooling can sustain hundreds of thousands of molding cycles with minimal wear.

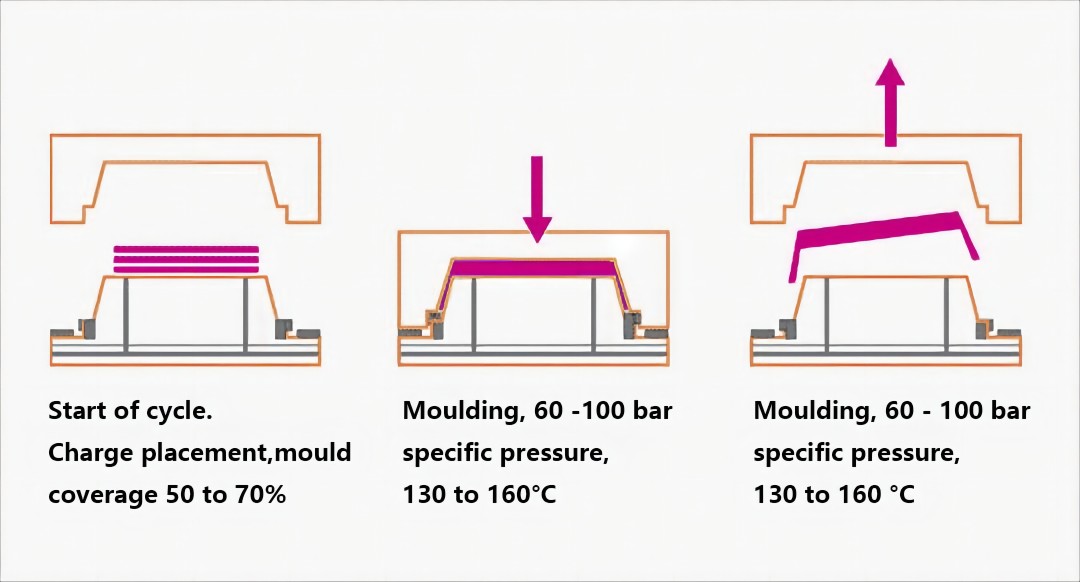

SMC Molding Process Using SMC Tool

The compression molding process using an SMC tool generally follows these steps:

- Material Loading: A pre-weighed SMC charge is placed in the open mold cavity.

- Mold Closing: The mold closes under high pressure (500–2000 tons depending on part size).

- Compression & Curing: Heat and pressure cause the material to flow and cure in the mold (typically 2–5 minutes).

- Part Ejection: The mold opens and the cured part is removed by ejector pins or vacuum assistance.

This method ensures minimal material waste and excellent mechanical properties, particularly in load-bearing applications.

SMC Tool Design Considerations

Precision mold design is essential to achieving optimal part quality. Important considerations include:

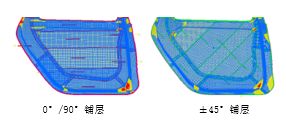

- Flow Simulation: Helps predict how the SMC material will fill the mold to avoid short shots or weld lines.

- Parting Line Optimization: Reduces flash and simplifies mold maintenance.

- Draft Angles: Ensures easy demolding of parts without surface damage.

- Ventilation: Proper venting prevents trapped air that can cause burn marks or voids.

- Thermal Control: Uniform temperature distribution minimizes warpage and shrinkage.

Choosing a Reliable SMC Tool Manufacturer

Investing in a high-quality SMC mold begins with selecting the right tooling partner. Look for:

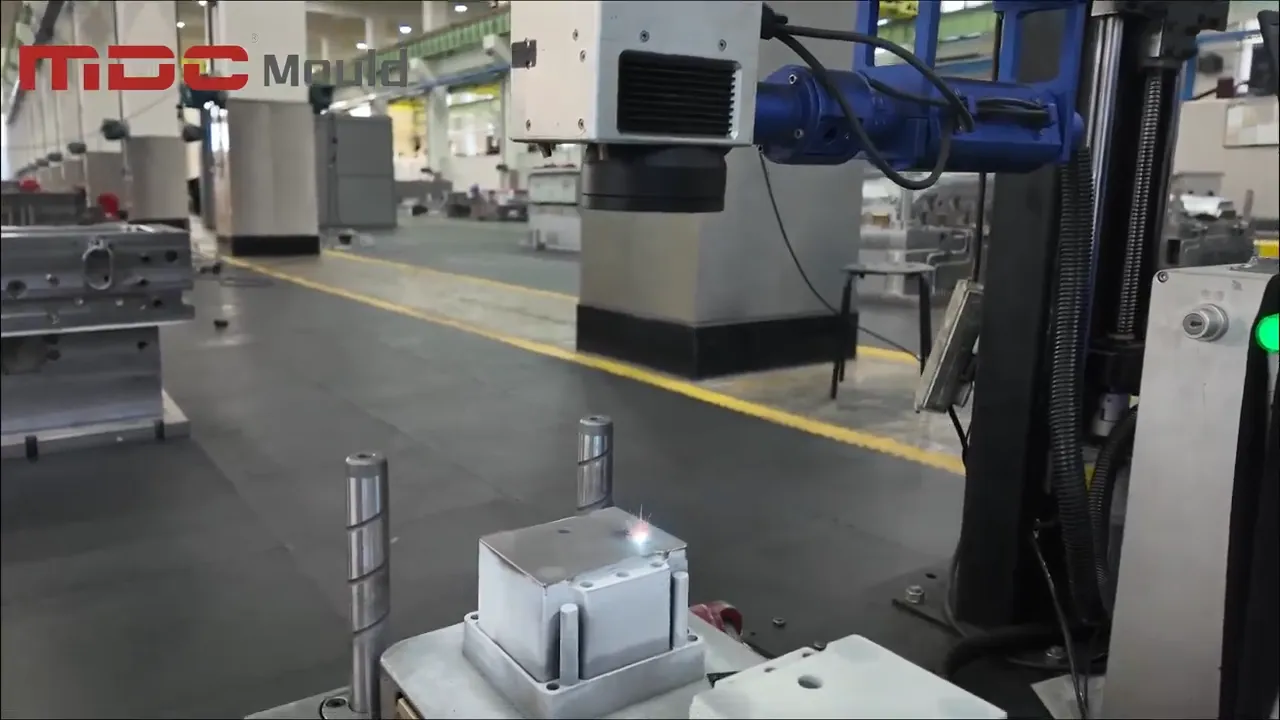

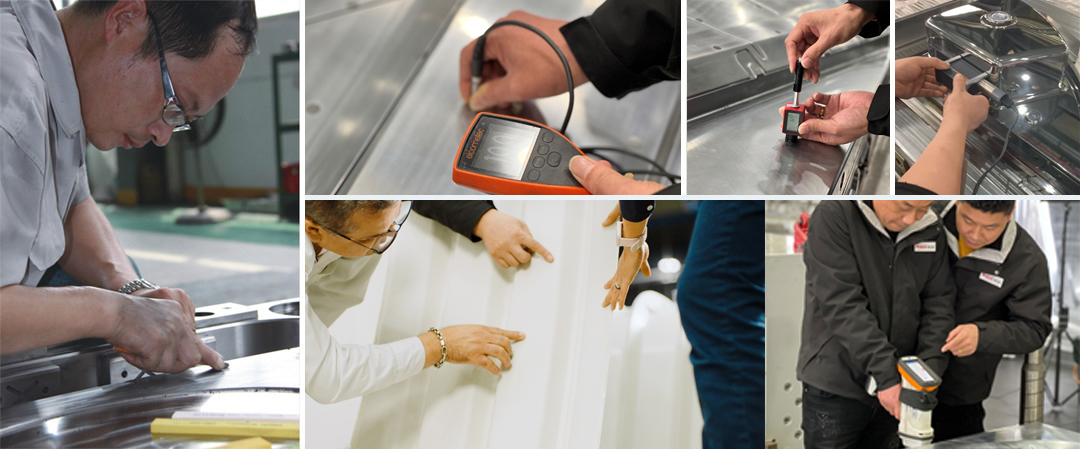

- Experience: Proven track record in SMC mold design and manufacturing.

- In-House Engineering: CAD/CAM expertise, flow analysis, and rapid prototyping capabilities.

- Material Knowledge: Ability to match resins, fillers, and fibers with the appropriate tooling materials.

- Global Support: Technical service and after-sales support in your region.

- Certifications: Compliance with ISO, automotive (IATF 16949), or other relevant standards.

Companies like MDC Mould in China are recognized for delivering advanced compression molds and SMC tooling for global composite manufacturers.

Conclusion: The Role of SMC Tools in Modern Composites

As the demand for lightweight, durable, and cost-effective composite components increases, the importance of precision SMC tools continues to grow. Whether you’re producing automotive body panels, structural parts, or electrical enclosures, a well-designed and expertly built SMC mold is essential for efficient production and superior part quality. Investing in reliable SMC tooling means investing in long-term performance, product consistency, and innovation in thermoset composite manufacturing.