In the ever-evolving landscape of manufacturing, the debate between traditional materials and advanced composites continues. One significant area of consideration is trim for doors, where the choice between composite moulding and wood trim can greatly impact the quality and longevity of the final product. This article delves into the superiority of MDC Mould’s composite trim over traditional wood, shedding light on the benefits that make these products stand out in the market.

Advantages of SMC Door Skin Mould and SMC Door Mould:

Durability Beyond Compare: MDC Mould’s SMC (Sheet Molding Compound) technology ensures unparalleled durability. Unlike wood, SMC resists warping, rotting, and deterioration caused by moisture or extreme weather conditions. This longevity factor significantly extends the lifespan of doors and trims.

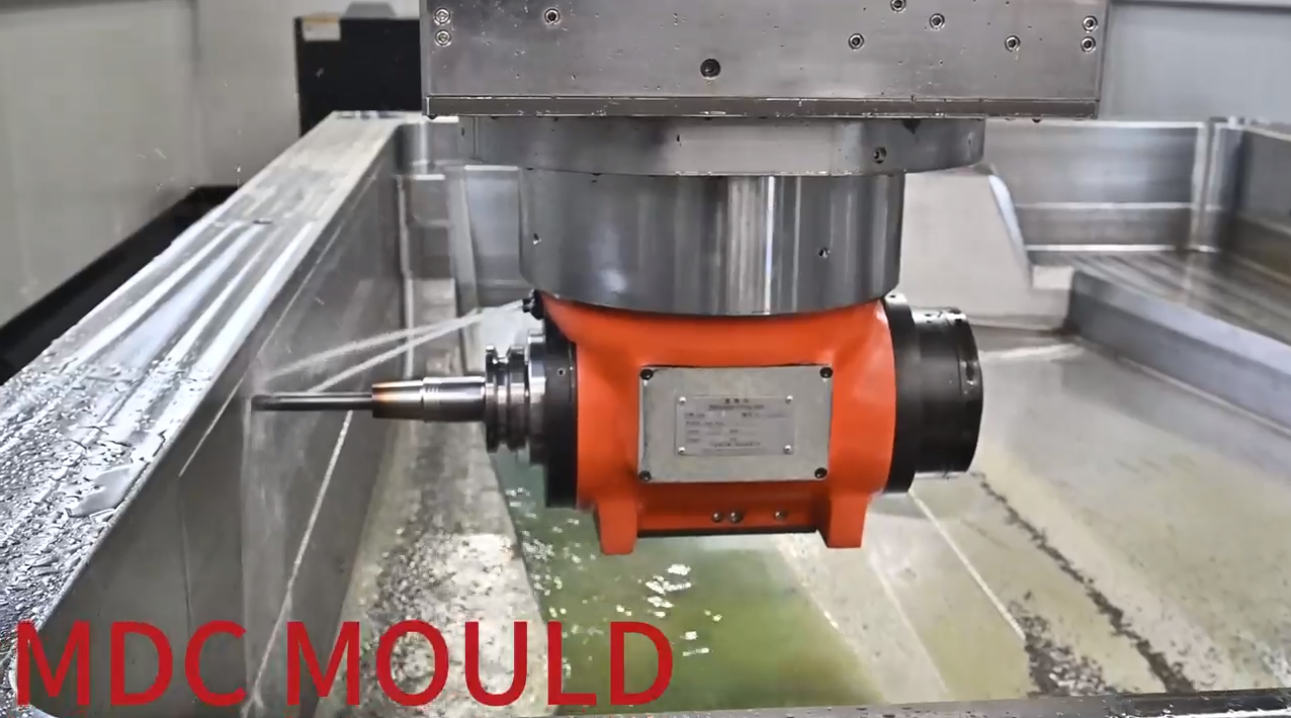

Versatility in Design: SMC Door Skin Mould and SMC Door Mould by MDC provide unparalleled flexibility in design. The molding process allows for intricate detailing, sharp lines, and complex patterns that may be challenging to achieve with wood. This versatility opens up a world of creative possibilities for architects and designers.

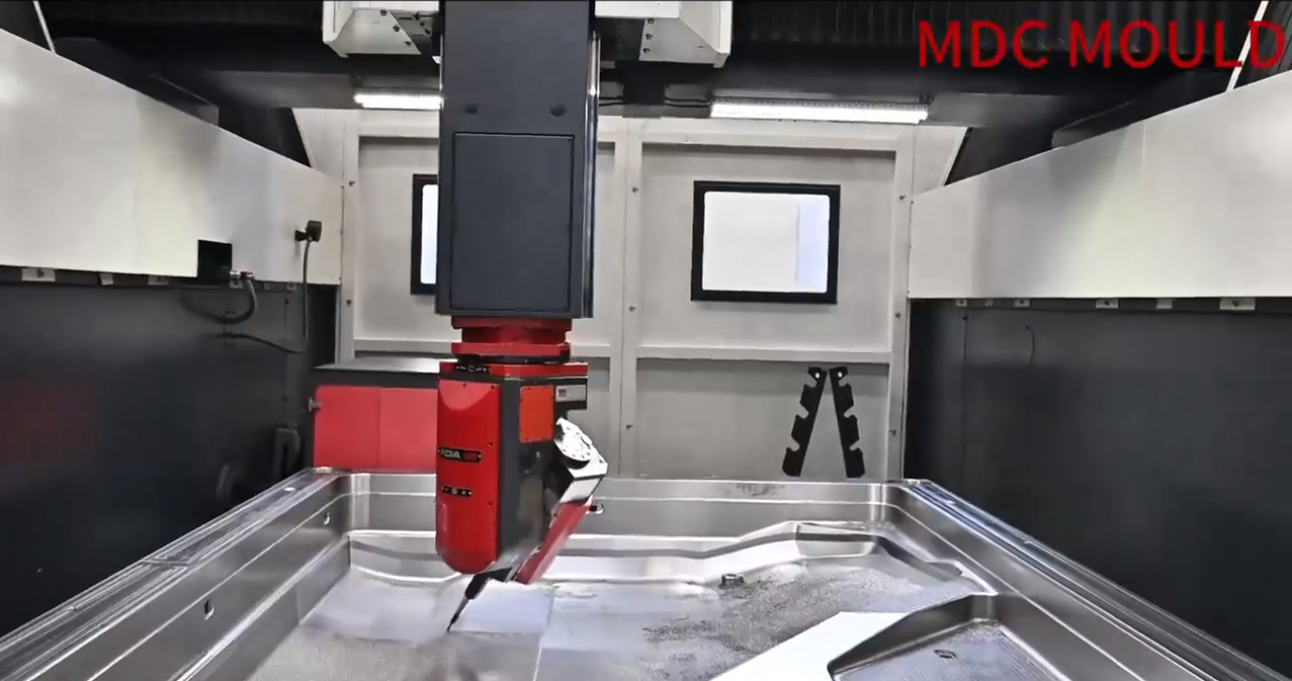

Consistency and Precision: Composite moulding ensures consistency in production, eliminating the natural variations found in wood. MDC Mould’s advanced manufacturing processes guarantee precise replication of designs, resulting in uniform and high-quality trims for every door.

Weather Resistance: Wood trim is susceptible to damage from exposure to the elements. In contrast, SMC Door Skin Mould and SMC Door Mould are engineered to resist UV rays, temperature fluctuations, and moisture, making them ideal for both indoor and outdoor applications.

Environmental Sustainability: MDC Mould is committed to environmentally friendly practices. The use of composite materials in SMC Door Skin Mould and SMC Door Mould reduces dependence on traditional wood sources, contributing to sustainable manufacturing practices.

Ease of Maintenance: Composite moulding requires minimal maintenance compared to wood. The non-porous surface of SMC makes it resistant to stains and easy to clean, ensuring a lasting aesthetic appeal with minimal effort.

In the ongoing debate between traditional and modern materials, MDC Mould’s SMC Door Skin Mould and SMC Door Mould emerge as superior choices for door trim applications. The fusion of durability, design versatility, and environmental responsibility positions these products as benchmarks in the composite moulding industry. Embrace innovation, choose MDC Mould, and elevate your doors to a new standard of excellence.