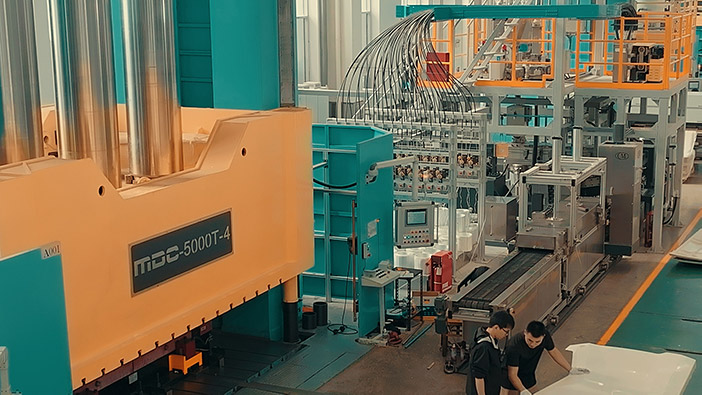

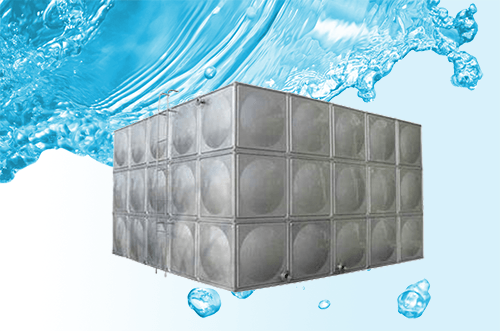

Manufactured by MDC Mould, these tanks are engineered to meet the highest standards of quality, durability, and hygiene, making them an ideal choice for a wide range of applications in the drinking water sector.

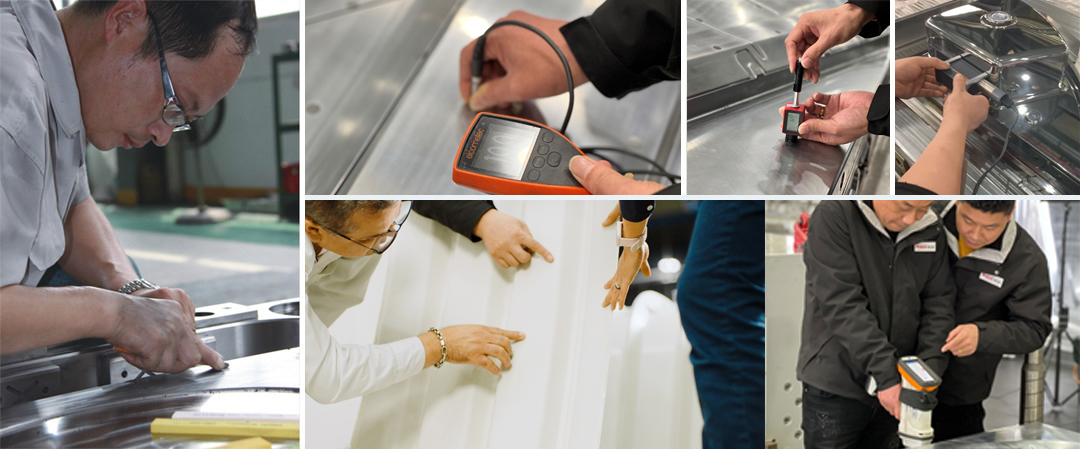

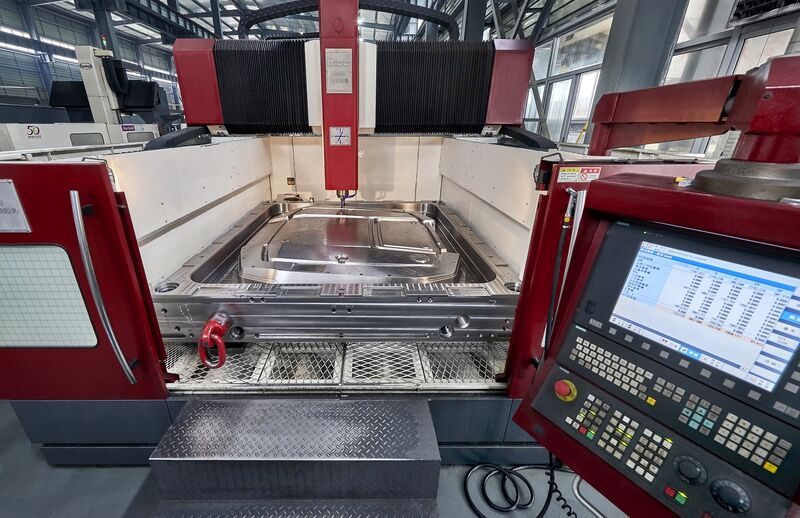

Quality Assurance:

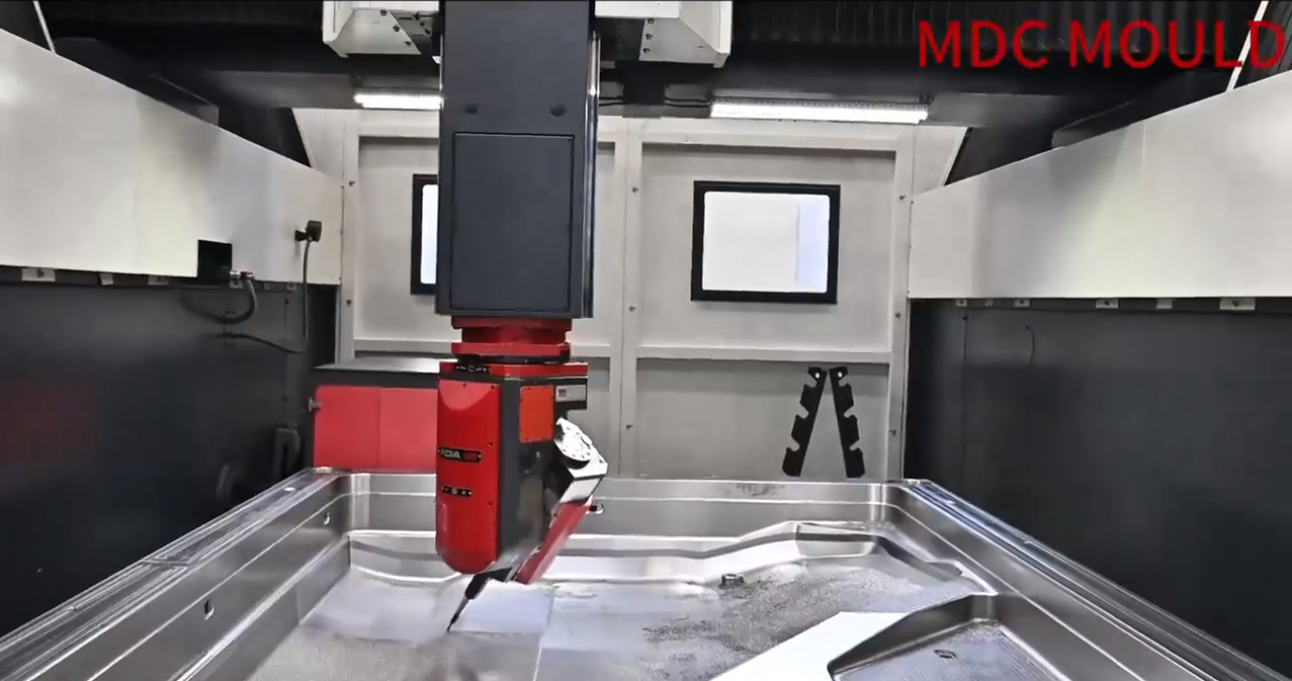

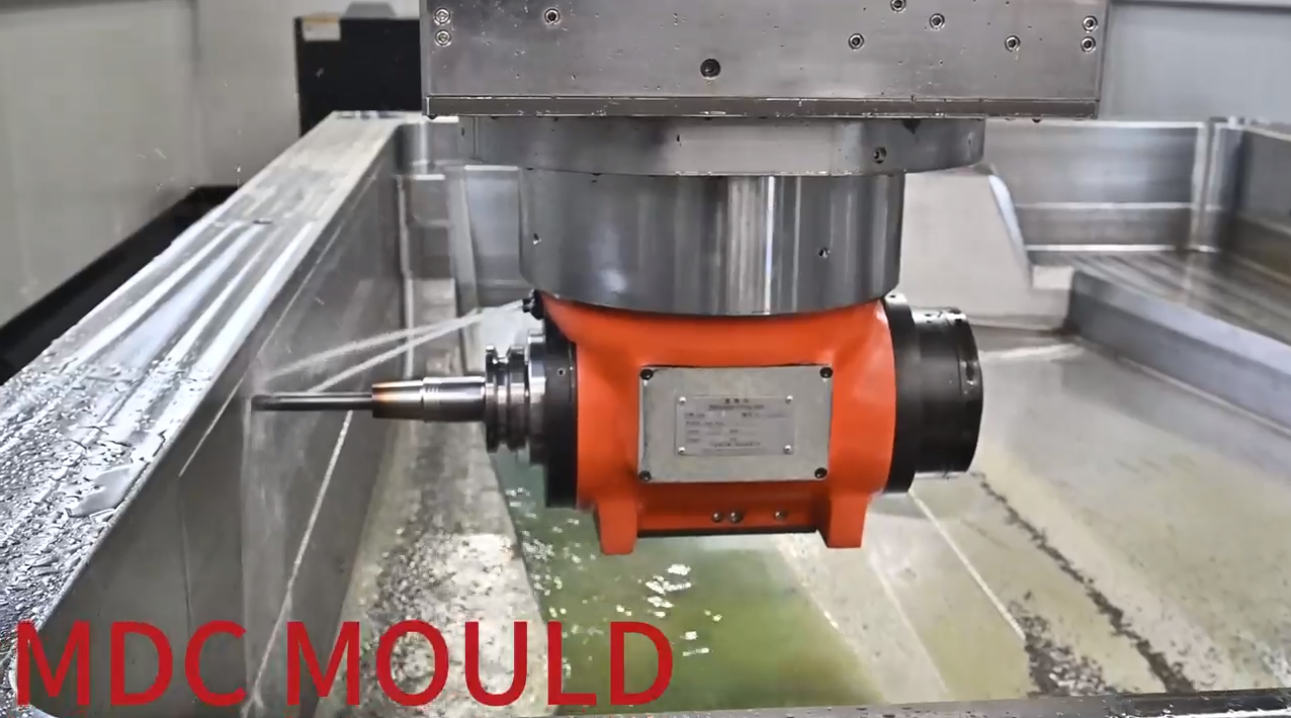

At MDC Mould, we prioritize quality assurance at every step of the manufacturing process. SMC (Sheet Molding Compound) materials used in the construction of our water tanks are rigorously tested to ensure they meet regulatory requirements and industry standards for drinking water storage. Our tanks undergo comprehensive quality checks, including pressure testing, structural integrity assessment, and leakage detection, to guarantee their reliability and longevity.

Hygienic Design:

Maintaining water purity is paramount in any drinking water application. Our SMC water tanks feature a hygienic design that minimizes the risk of contamination. The smooth, non-porous surface of the tanks prevents the growth of bacteria and algae, ensuring that the water remains safe for consumption. Additionally, our tanks are equipped with secure sealing mechanisms to prevent ingress of external pollutants, further safeguarding the integrity of the stored water.

Durability and Sustainability:

SMC water tanks are renowned for their durability and longevity. Constructed from high-quality composite materials, they are resistant to corrosion, rust, and UV degradation, making them suitable for both indoor and outdoor installations. Moreover, their lightweight yet robust construction simplifies transportation, installation, and maintenance processes, reducing overall costs and environmental impact.

Versatile Applications:

The versatility of SMC water tanks makes them adaptable to various drinking water applications. From rural communities to urban infrastructure projects, our tanks serve as dependable storage solutions for potable water supply systems, emergency water reserves, and water treatment facilities. Whether installed aboveground, underground, or as part of a modular system, SMC water tanks deliver consistent performance and peace of mind.

Conclusion:

In the pursuit of ensuring access to safe drinking water for all, SMC water tanks from MDC Mould emerge as a reliable and indispensable resource. With their uncompromising commitment to quality, hygiene, durability, and versatility, these tanks stand as a testament to our dedication to excellence in the field of water storage solutions. As communities around the world continue to prioritize water safety and sustainability, SMC water tanks remain at the forefront, providing a foundation for healthier, more resilient societies.