Thermoforming and injection molding are two popular manufacturing processes used in the production of plastic parts. While both methods have their advantages and disadvantages, many factors come into play when determining which is better for a specific application. At MDC Mould, we specialize in providing innovative solutions for our clients, including utilizing Sheet Molding Compound (SMC) Mould technology, which offers several distinct advantages over traditional methods.

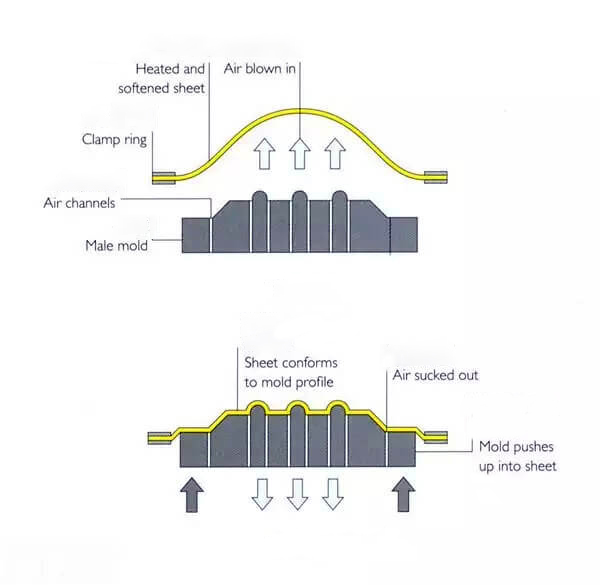

Thermoforming is a process where a thermoplastic sheet is heated to a pliable forming temperature, then formed to a specific shape in a mold, either by vacuum forming, pressure forming, or mechanical forming. On the other hand, injection molding involves injecting molten plastic material into a mold cavity, where it cools and hardens to the desired shape. Both processes have their strengths, but thermoforming, particularly with SMC Mould technology, offers several benefits:

Cost-Effectiveness: Thermoforming with SMC Mould technology typically requires lower tooling costs compared to injection molding. Since thermoforming molds are often made from less expensive materials like aluminum or composite, they are more affordable to manufacture and modify, making them a cost-effective option for low to medium volume production runs.

Faster Turnaround Times: SMC Mould technology allows for quicker production cycles compared to traditional injection molding methods. The simplicity of thermoforming molds means they can be produced and modified more rapidly, resulting in shorter lead times for parts production.

Design Flexibility: Thermoforming offers greater design flexibility, especially when working with complex geometries or large parts. SMC Mould technology allows for easy incorporation of features such as undercuts, textures, and surface finishes, giving designers more creative freedom in their designs.

Material Versatility: Thermoforming can be used with a wide range of thermoplastic materials, including ABS, PVC, polycarbonate, and polypropylene, among others. This versatility allows for the selection of the most suitable material for specific application requirements, whether it be for its mechanical properties, chemical resistance, or aesthetic appeal.

Sustainability: Thermoforming with SMC Mould technology is often considered a more sustainable option compared to injection molding. Since thermoforming typically produces less waste material and consumes less energy during the manufacturing process, it can be a greener choice for environmentally conscious businesses.

At MDC Mould, we leverage our expertise in SMC Mould technology to provide innovative thermoforming solutions that meet the diverse needs of our clients. By combining cost-effectiveness, speed, design flexibility, material versatility, and sustainability, thermoforming with SMC Mould technology offers numerous advantages over traditional injection molding methods. Contact us today to learn more about how we can help bring your plastic part designs to life with our cutting-edge manufacturing capabilities.