MDC wants to tell suppliers why we choose to make SMC molds through this article.

Regarding the origin of the name MDC, MDC means the foothold of manufacture, development and creation.This is also the purpose of our manufacturing mold practice.

Let’s first understand the manufacturing process of SMC mold.

Moulding of SMC mould Parts:

Moulding is made in heated steel tools at temperatures between 125°C and 170°C. It is very important to take note of the setup instructions of each specific material due to the variety of formulations. All known processes are possible as the material will be tailor made for your specific process and application.

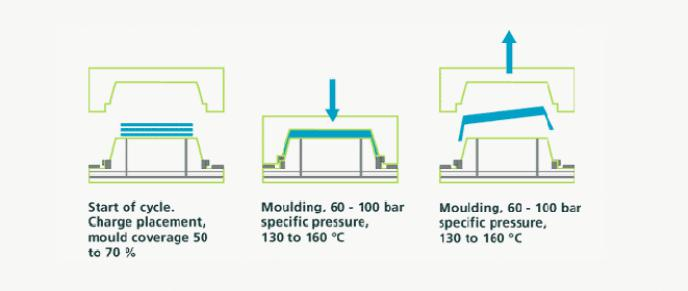

Compression moulding cycle

Layers of SMC are placed into the heated tool. Through closing the tool the material fills the cavity and polymerizes. After complete cure the parts are released hot. With compression moulding highest mechanical strengths can be achieved.

Applications

Market penetration for SMC mould is gaining ground in terms of both end-use applications and global demand. Suppliers are reporting more interest in SMC from industrial, consumer, building and construction, energy generation, electrical / electronic, non-automotive transportation, and even aerospace customers.

Increasing performance demands in automotive, electrical, appliance, food service, and energy industries, among others, plus the rising cost of cast metals, is prompting design engineers to consider metals conversion to alternate materials for new products. Thermoset composites have many unique properties – exceptional strength, light weight, corrosion resistance, UV resistance, electrical non-conductance, exceptional thermal properties – that make them desirable over thermoplastics and, in particular, metals, such as cast steel and aluminum.

For instance, thermoset composite materials can be used outdoors and in extreme environments, as they will not rust or corrode. And, because many components can be molded along with the part, and require no final finishing, they are often more economical from a total manufacturing standpoint.

MDC has excellent designers, perfect equipment and strict testing links, we will make customers feel the greatest sincerity.

Please believe that MDC has many years of experience in SMC mold design and manufacturing, which can meet your needs.

obviously like your web-site however you need to test the spelling on several of your posts. A number of them are rife with spelling problems and I in finding it very troublesome to tell the reality nevertheless I’ll surely come again again.