SMC (Sheet Molding Compound) compression molding is a widely used manufacturing process for producing high-strength, complex-shaped composite components. As an employee of MDC Mould, we specialize in providing innovative solutions and expertise in SMC compression molding. In this article, we will explore the process of SMC compression molding, highlighting its key steps and benefits.

1. Material Preparation:

The SMC material consists of chopped glass fibers, thermosetting resin, fillers, and additives. The first step in the process is to accurately weigh and mix these components to achieve the desired material properties. The mixture is then formed into a sheet or mat for further processing.

2. Mold Preparation:

The mold plays a crucial role in the SMC compression molding process. It is designed to the exact specifications of the desired part and is typically made from steel or aluminum. Prior to molding, the mold surfaces are cleaned, treated with release agents, and heated to the required temperature to facilitate resin curing.

3. Loading the Mold:

Next, the SMC material is carefully placed into the mold cavity in the desired orientation and thickness. This step requires precision to ensure uniform distribution of the material and avoid air entrapment.

4. Compression Molding:

Once the mold is loaded, it is closed, and hydraulic pressure is applied to compress the SMC material. The pressure forces the material to flow and conform to the shape of the mold cavity, resulting in the desired part geometry. The applied pressure also facilitates resin curing, ensuring the part retains its shape and strength.

5. Curing:

After compression, the mold remains closed while the SMC material undergoes curing. Heat is applied to accelerate the curing process, typically through convection or infrared heating systems. Curing times vary depending on the part size, complexity, and resin formulation but typically range from a few minutes to several hours.

6. Demolding:

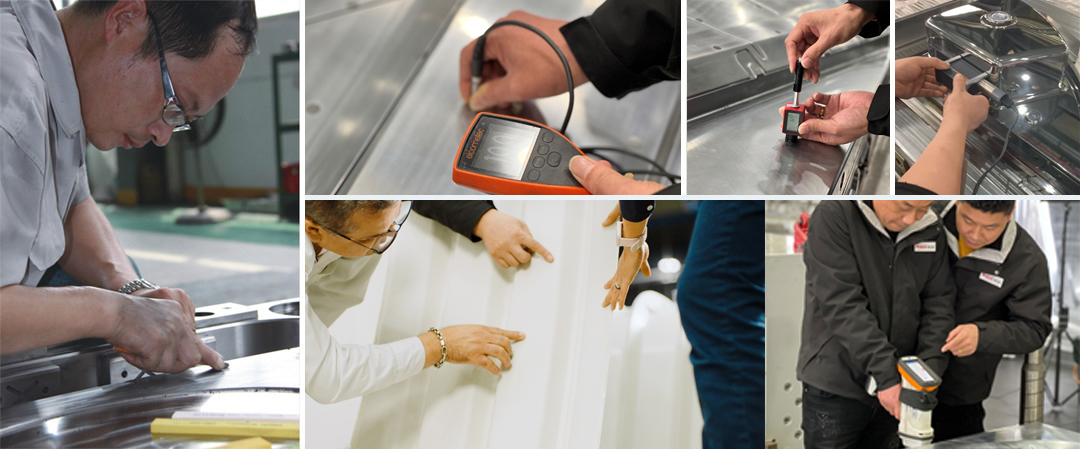

Once the curing process is complete, the mold is opened, and the cured part is carefully removed. Demolding requires precision to prevent damage to the part and mold surfaces. Any excess material or flash is trimmed from the part, and it undergoes inspection to ensure it meets quality standards.

Benefits of SMC Compression Molding:

- High Strength: SMC parts exhibit excellent mechanical properties, including high strength-to-weight ratios and stiffness.

- Design Flexibility: SMC compression molding allows for the production of complex geometries with tight tolerances, offering design freedom for innovative solutions.

- Cost-Effectiveness: SMC materials are relatively low-cost compared to other composites, making them a cost-effective choice for large-scale production.

- Corrosion Resistance: SMC parts are inherently resistant to corrosion, making them ideal for applications in harsh environments.

In conclusion, SMC compression molding is a versatile and efficient manufacturing process for producing high-quality composite components. As experts in SMC compression molding, MDC Mould is committed to delivering innovative solutions and superior products to our customers. Contact us to learn more about our capabilities and how we can assist with your SMC compression molding needs.