MDC’s vacuum forming technology is a technology in which the mold is extracted from the air in the process of pressing the air, and the mold is usually produced and manufactured. MDC mold also adopts vacuum forming technology, which has a long service life, light weight and high strength, and is not easy to corrode.

Principle of vacuum forming mold:

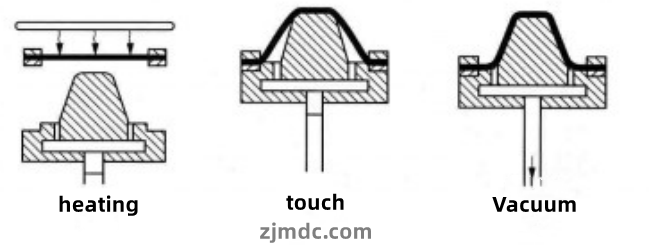

Vacuum forming is to fix the thermoplastic sheet and sheet on the mold, heat it with a radiant heater to reach the softening temperature, and then use a vacuum pump to remove the air between the mold and the plate (sheet), so that the plate (sheet) The material parison is formed according to the contour of the mold. With the increase of the vacuum degree, the forming pressure under the parison is only 0.06-0.085MPa, while the air pressure above the parison remains at about 0.1 MPa. After cooling and setting, the product is blown out of the mold with compressed air and demolded.

Vacuum forming mold forming method:

Vacuum forming methods mainly include concave mold vacuum forming, punch vacuum forming, concave and convex mold vacuum forming successively, bubble blowing vacuum forming, auxiliary punch vacuum forming and vacuum forming with gas buffer device.

Advantages of vacuum forming molds:

(1) Saving raw and auxiliary materials, light weight, convenient transportation, good sealing performance, and meeting the requirements of environmental protection and green packaging;

(2) It can pack any special-shaped products without additional buffer materials;

(3) The packaged products are transparent and visible, beautiful in appearance, and easy to sell;

(4) The packaged products are suitable for mechanized and automated packaging, which facilitates modern management, saves manpower and improves efficiency.

MDC has been using vacuum forming technology, focusing on composite molds and molding molds, is a very professional SMC mold manufacturer, mainly engaged in SMC molds, BMC molds, GMT molds, LFT molds, etc., glass fiber reinforced plastic molds and carbon fiber molds These hot pressing molds The design, development and manufacture of the company’s molds are deeply trusted by customers.