SMC (Sheet Molding Compound) is a high-strength, lightweight composite material composed of resin, glass fiber, and fillers. SMC molds are commonly used to manufacture various types of complex shaped parts, such as automotive shells, aircraft components, ship parts, and so on. Therefore, in the manufacturing process of SMC molds, machining accuracy is a very important aspect.

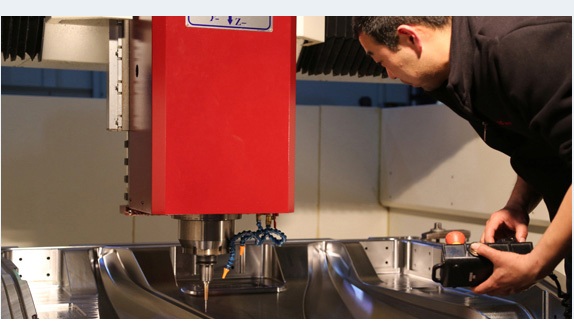

As a professional SMC mold manufacturer, MDC Mould is equipped with experienced engineers, imported equipment, and sophisticated processing processes that can meet customer quality requirements. Today we will introduce the Spark Erosion Machine used in MDC Mould.

Spark Erosion Machine, also known as electrical discharge machining machines, is a method of cutting workpieces through electrical discharge. In this process, the gap between the electrode and the workpiece is filled with a liquid medium (usually deionized water), which can generate electrical discharge between the electrode and the workpiece, and can also wash away the debris of the material being cut.

The main working principle of a spark erosion machine is to generate electrical pulses on the surface of the workpiece to discharge electricity, which ionizes the medium between the electrode and the workpiece, thereby generating a series of electric spark discharge phenomena. Each electric spark discharge process will impact and detach small particles on the surface of the workpiece, and the electrode will gradually consume. Through repeated electric spark discharge processes, small particles on the surface of the workpiece are gradually worn and reduced, ultimately forming the desired shape and profile.

Advantages: The spark erosion machine has high machining accuracy and can accurately process complex shapes and contours in SMC molds. That is to say, the obtained SMC mold not only has high accuracy, but also has high surface quality. At the same time, the processing process of a wire cutting machine does not generate thermal deformation or cutting stress, so it does not adversely affect the performance of SMC materials. This makes spark erosion machine one of the ideal choices for manufacturing SMC molds.

In short, as a well-known compression mold manufacturer at home and abroad, if you have any needs, then MDC Mould will be your best choice.