In modern manufacturing, mold is a key production tool, which is widely used in the manufacturing process of various products. In the production of composite products, Sheet Molding Compound (SMC) mold is a special type of mold. SMC is a high-performance composite material composed of resin, glass fiber and fillers. It has the advantages of light weight, high strength and corrosion resistance. It is widely used in automotive, aerospace, construction and other fields. However, in order to produce high-quality SMC products, die design is a crucial link.

Die design refers to the comprehensive consideration of various factors such as reasonable mold structure, material selection, product design and mold processing in the manufacturing process of SMC molds, so that the mold can be realized in the production process efficient and stable production, and guarantee the quality and performance of the final product. High-quality SMC mold design should have the following characteristics.

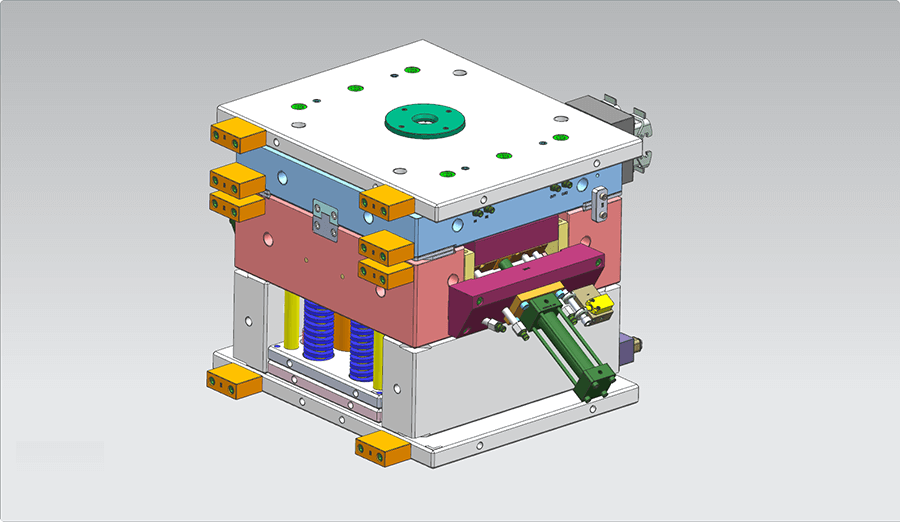

Reasonable mold structure

Reasonable mold structure is the basis of high-quality SMC molds. The rationality of the mold structure directly affects the molding quality and production efficiency of SMC products. When designing the mold structure, factors such as the fluidity, shrinkage, and shrinkage rate of the SMC material need to be considered to ensure that the SMC material can fully flow in the mold cavity and fill every detail when the mold is closed. At the same time, the mold structure should take into account the shrinkage and deformation of the product to ensure the dimensional accuracy and shape consistency of the final product. In addition, a reasonable cooling system design is also a part that cannot be ignored in the mold structure, which can effectively control the mold temperature, improve production efficiency and prolong the life of the mold.

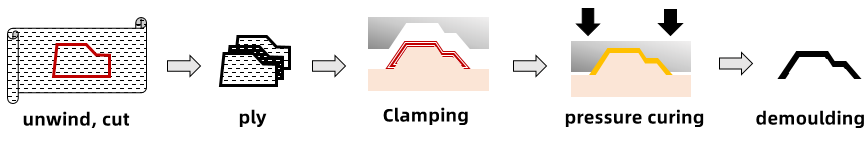

Release performance of SMC mold

SMC materials usually require a long curing and hardening process in the mold, therefore, the release performance of the product has a direct impact on the life of the mold and production efficiency. Reasonable product design should include proper demoulding slope, demoulding sequence, demoulding force, etc., so that when the mold is demolded, it can be easily separated from the mold without damaging the product or the mold.

Characteristics of SMC materials

Product design also has an important impact on the quality and performance of SMC molds. Product design should fully take into account the characteristics of SMC materials, including its fluidity, shrinkage, molding difficulty, etc. Reasonable product design can reduce the internal stress and deformation of SMC materials during the molding process, thereby ensuring the dimensional accuracy and appearance quality of the final product. In product design, it is necessary to reasonably set parameters such as product wall thickness, line angle, corner radius, etc., so as to obtain good filling effect and finished product quality during mold molding.

suitable material selection

The mold material should have the characteristics of high strength, high hardness, wear resistance and corrosion resistance, so as to ensure that the mold will not have problems such as deformation, wear and corrosion during the long-term production process. At the same time, the mold material should also have good thermal conductivity in order to better control the mold temperature and improve production efficiency. In terms of material selection, it is necessary to comprehensively consider factors such as the use environment of the mold, production batch, product requirements, etc., and choose a suitable mold Material.

Structural Strength and Stability

SMC products usually need to have high strength and stability to meet their requirements in practical applications. In product design, it is necessary to fully consider the mechanical properties of SMC materials, and reasonably set the wall thickness, ribs, support structures, etc. of the product to ensure the strength and stability of the final product.

Precision and quality of mold processing

High-precision mold processing can ensure the dimensional accuracy and shape consistency of the mold, thereby ensuring the quality of the final product. In mold processing, it is necessary to pay attention to the dimensional control, surface finish, surface coating, etc. of the mold to ensure the appearance quality and performance of the final product. At the same time, high-quality equipment can also improve the precision of the mold.

In conclusion, a good quality SMC mold comes from a good die design. Reasonable mold structure, appropriate material selection, full consideration of product design, and high-precision mold processing are all important factors to ensure the quality and performance of SMC molds. In the design and manufacturing process of SMC molds, the above factors need to be considered comprehensively to ensure that the molds can achieve efficient and stable production in the production process, and produce high-quality SMC products to meet the ever-growing market demand.

As a professional mold maker, MDC Mould has a team of experienced engineers using the latest engineering tools and software to help you build high-quality SMC mold. This also enables our tooling engineers to create the best and most cost-effective tooling for your project requirements. We can review your CAD files or part drawings and provide feedback on possible quality issues or areas for improvement to help ensure your product is manufacturable. We support a wide variety of file formats, including major software. MDC Mould can also create a full 3D model of your target part, or we can convert your 2-D drawing into a 3-D solid CAD model. If you have any needs, welcome to contact us.