In recent years, the landscape of industries has been undergoing a transformative shift, driven by the innovative manufacturing of composite materials. MDC Mould, a pioneering player in the field, is at the forefront of this revolution, redefining the way products are made across various sectors.

What is Composite Manufacturing?

Composite manufacturing involves the fusion of two or more materials to create a product that is stronger and more durable than its individual components. These materials consist of a matrix, which serves as the base material bonding with reinforcement materials. Notably, woven composites are increasingly replacing traditional metals like steel in various applications.

Carbon Fiber Composites: A Game-Changer

Among the most prevalent composite materials is carbon fiber composite. Renowned for its effectiveness, carbon fiber composites boast a robust structure with tightly bonded carbon atoms. These composites exhibit excellent chemical resistance, coupled with the advantages of being lightweight and heat-resistant. The weight-to-strength ratio of carbon fiber is double that of aluminum, making it a preferred choice for manufacturers.

Applications in Aerospace Manufacturing

MDC Mould, specializing in composite mold manufacturing, has developed cutting-edge products catering to the aerospace industry’s demand for durable and lightweight components. Commercial aircraft, for instance, leverage carbon fiber to reduce weight, subsequently lowering fuel consumption—a critical factor in the face of increasingly stringent carbon emission regulations. This approach not only contributes to environmental sustainability but also reduces fuel and component costs.

Furthermore, carbon fiber composites find applications in spacecraft, air taxis, and 3D-printed components, showcasing their versatility in aerospace manufacturing.

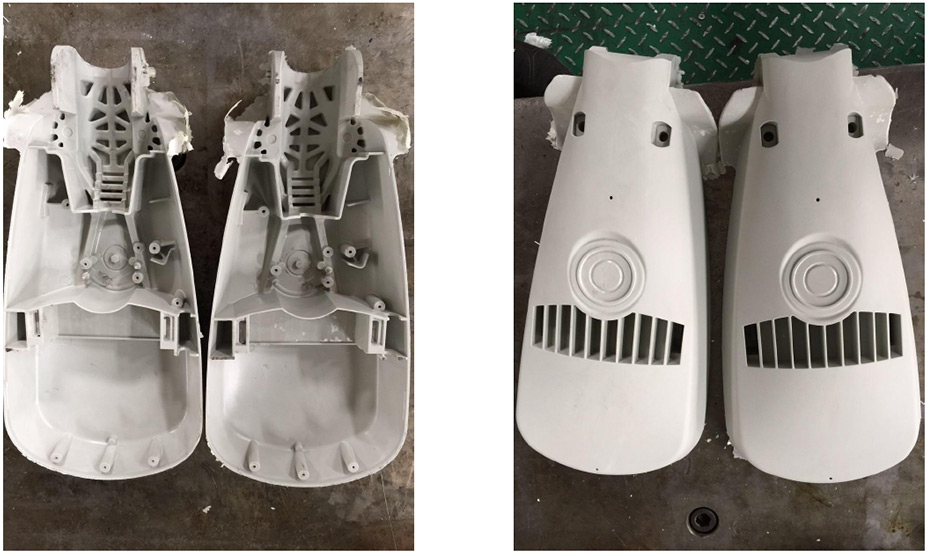

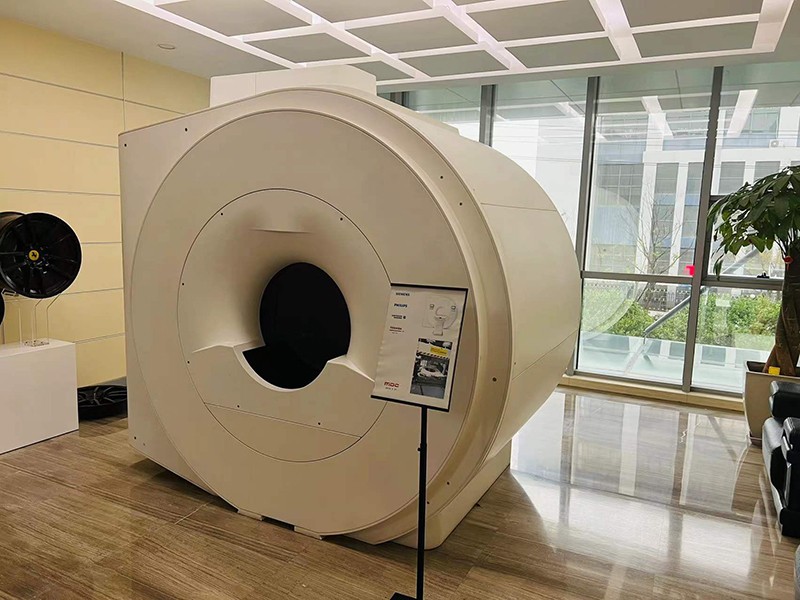

Medical Advancements with Composite Materials

The medical sector, recognizing the benefits of carbon fiber composites, has embraced these materials to enhance the longevity of medical equipment. Initially used in aerospace and automotive components, Carbon Fiber Reinforced Polymers (CFRP) are now making significant strides in medical applications due to their superior performance compared to traditional metals.

Implants made from carbon fiber facilitate faster recovery for patients and provide radiolucency, allowing surgeons a clear view of fractures during and after surgery.

MDC Mould: Leading the Composite Manufacturing Frontier

MDC Mould has been instrumental in driving the lightweight and durable aspects of composite materials, particularly carbon fiber, to the forefront of aerospace and medical manufacturing. As industries continue to evolve, MDC Mould remains a leader in pushing the boundaries of what is possible in composite manufacturing.

Модульные кухни в Новосибирске – воплощение ваших желаний

модульная кухня https://modulnie-kuhni-novosibirsk.ru .