A recent computational analysis demonstrates that DMLS-produced metal molds—featuring honeycomb internal structures—can meet the structural and thermal demands of compression molding while reducing material usage by up to 74% compared to conventionally machined molds. This breakthrough has direct implications for high-precision SMC mold, compression mold, and advanced composite tooling applications.

Executive summary

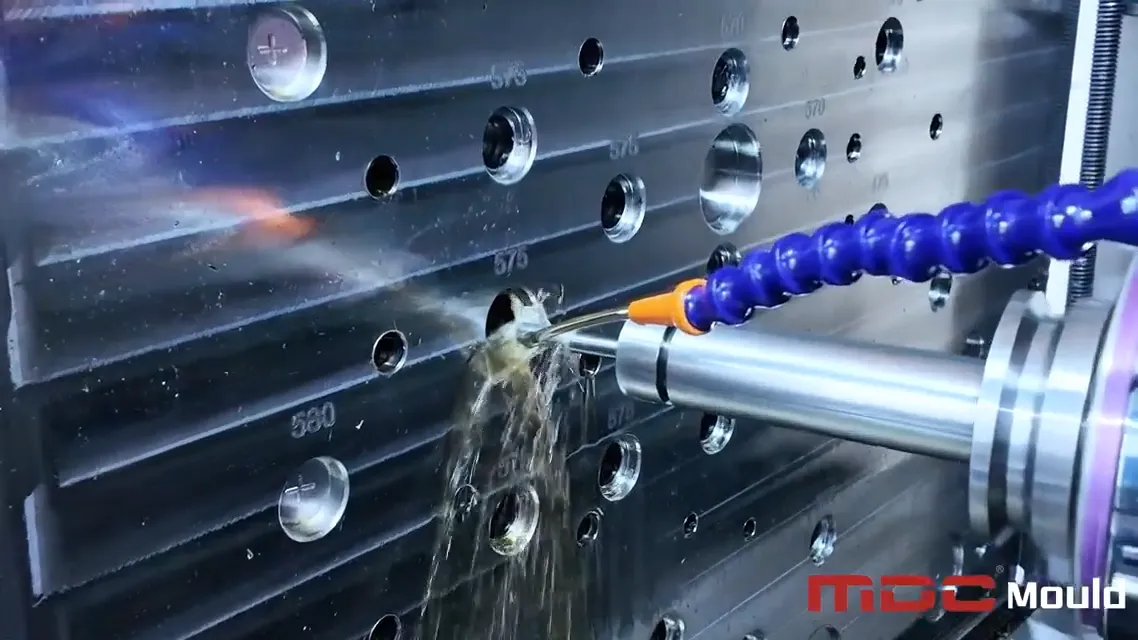

Traditional compression mold fabrication relies on subtractive machining—CNC milling, turning, and EDM—to produce high-precision tooling. While accurate, these methods incur long lead times, high tooling steel consumption, and substantial material waste. The computational study summarized here evaluates Direct Metal Laser Sintering (DMLS) as an alternative production route for compression mold tooling. Key findings include:

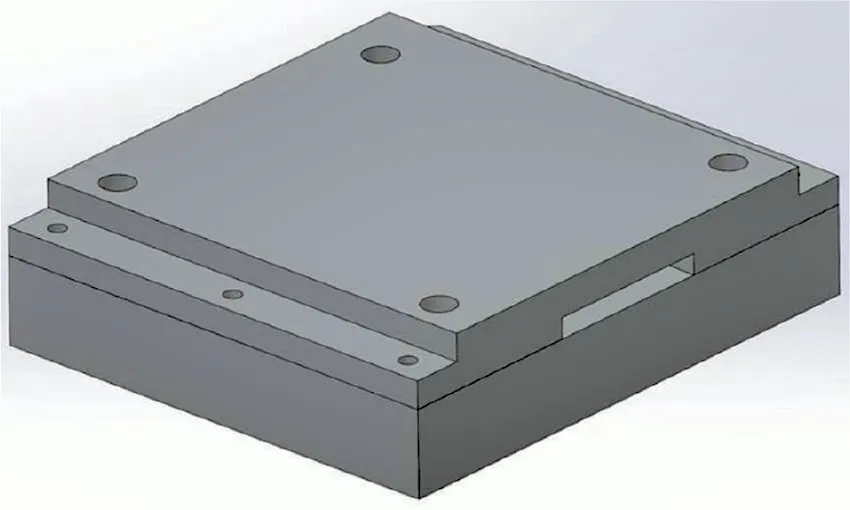

- DMLS mold with an internal honeycomb lattice achieved the design criterion of maximum deflection ≤ 0.001 inches under realistic molding pressures and temperatures.

- The additive mold used approximately 74% less material than a conventionally machined equivalent.

- Design freedom enabled by DMLS allows internal topology optimization, conformal cooling channel placement, and mass reduction without compromising stiffness.

1. Why DMLS matters for compression molds and SMC tooling

Direct Metal Laser Sintering (DMLS) is a powder-bed fusion metal additive manufacturing technology that constructs parts layer-by-layer using a focused laser to fuse metal powder. For compression mold and SMC mold manufacturers, DMLS offers several strategic advantages:

1.1 Material and cost efficiency

Additive lattice and honeycomb designs drastically reduce the volume of expensive tool steel required for large molds. The reported 74% material savings translate directly into lower material cost and reduced machining allowance when hybrid finishing (DMLS + CNC) is applied.

1.2 Geometric freedom and thermal control

DMLS enables features that are difficult or impossible to machine: internal lattices for light-weighting, integrated conformal cooling channels for thermal uniformity, and topology-optimized ribs that maximize stiffness per unit mass—capabilities that are especially beneficial for high-volume compression tooling.

1.3 Shorter development cycles

For R&D, prototype molds, or low-volume specialized tools, DMLS reduces lead times by removing complex multi-step machining processes. Iterations—such as channel geometry or reinforcement—can be implemented directly in the CAD model and printed without the need for expensive fixturing changes.

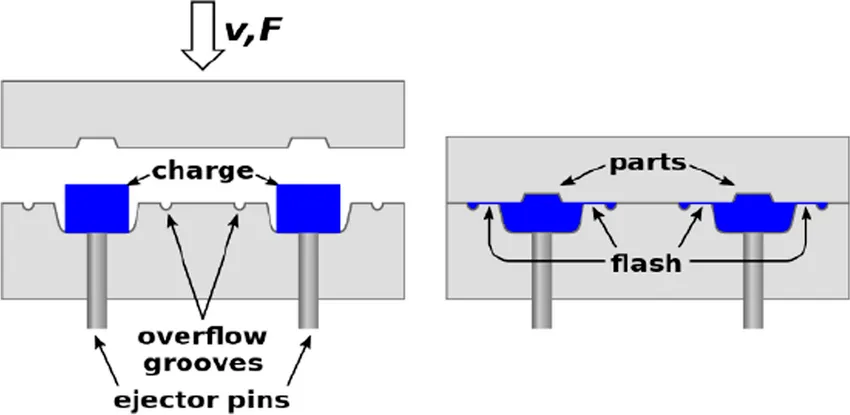

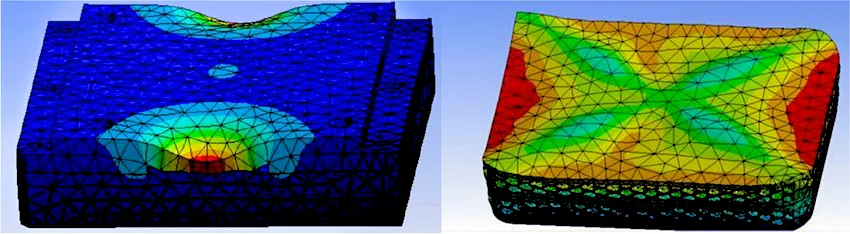

2. Computational approach: validating structural and thermal performance

The study compared two mold concepts under identical molding conditions: a solid machined steel mold (reference) and a DMLS-manufactured mold with a honeycomb internal structure. Finite Element Analysis (FEA) evaluated mechanical deflection under molding pressure and thermal gradients representative of SMC compression cycles.

2.1 Structural analysis

Using linear and non-linear static simulations, the DMLS honeycomb mold maintained a maximum deflection below the stringent tolerance of 0.001 inches. The lattice geometry was tuned to concentrate material along principal stress paths while removing mass in low-stress regions.

2.2 Thermal analysis

Transient thermal simulations modeled heat input during a typical compression-curing cycle and subsequent cooling. The DMLS mold’s lower thermal mass (due to internal cavities) required active thermal management—implemented via conformal cooling channels—to ensure uniform cure and avoid hot spots. With conformal cooling, temperature differentials were within acceptable process windows.

2.3 Hybrid finishing strategy

The research emphasized a hybrid workflow: DMLS for the internal topology and near-net shape plus precision CNC finishing on critical mating surfaces. This approach ensures required surface finish and dimensional tolerances, while still preserving the material and time advantages of additive production.

3. Design recommendations for metal-AM compression molds

Based on computational results and best practices, the following guidelines are recommended when applying DMLS to compression mold tooling:

- Topology-aware lattice design: Orient honeycomb or lattice reinforcement along primary load paths; avoid uniform porosity that undermines stiffness.

- Conformal cooling integration: Place channels close to the cavity surface with controlled channel cross-sections to optimize heat extraction and cycle time.

- Post-process planning: Design for CNC finishing allowance on sealing faces and parting lines; determine regions for stress-relief heat treatment to minimize residual stresses from AM.

- Material selection: Use tool steels and maraging steels compatible with DMLS and post-heat-treatment to achieve required hardness for long tool life.

- Quality assurance: Implement non-destructive testing (NDT) for internal porosity and coordinate metrology for cavity dimension verification.

4. Manufacturing, sustainability, and cost considerations

While DMLS reduces raw material waste, manufacturers must evaluate machine time, powder costs, and post-processing expenses. Key considerations include:

- Powder reuse strategies to minimize consumable costs.

- Energy consumption of large-format DMLS machines versus conventional machining centers.

- Tool life and maintenance: Ensure DMLS tool surface treatments or coatings to meet abrasive wear of SMC compounds.

- Lifecycle analysis: Lowered steel usage and reduced machining waste contribute positively to environmental impact when balanced against AM energy use.

Practical conclusion: For mid-to-high complexity molds and R&D tooling, DMLS (combined with CNC finishing) is often economically and technically superior. For simple, very large-volume tooling with minimal internal features, traditional machining may still be preferable.

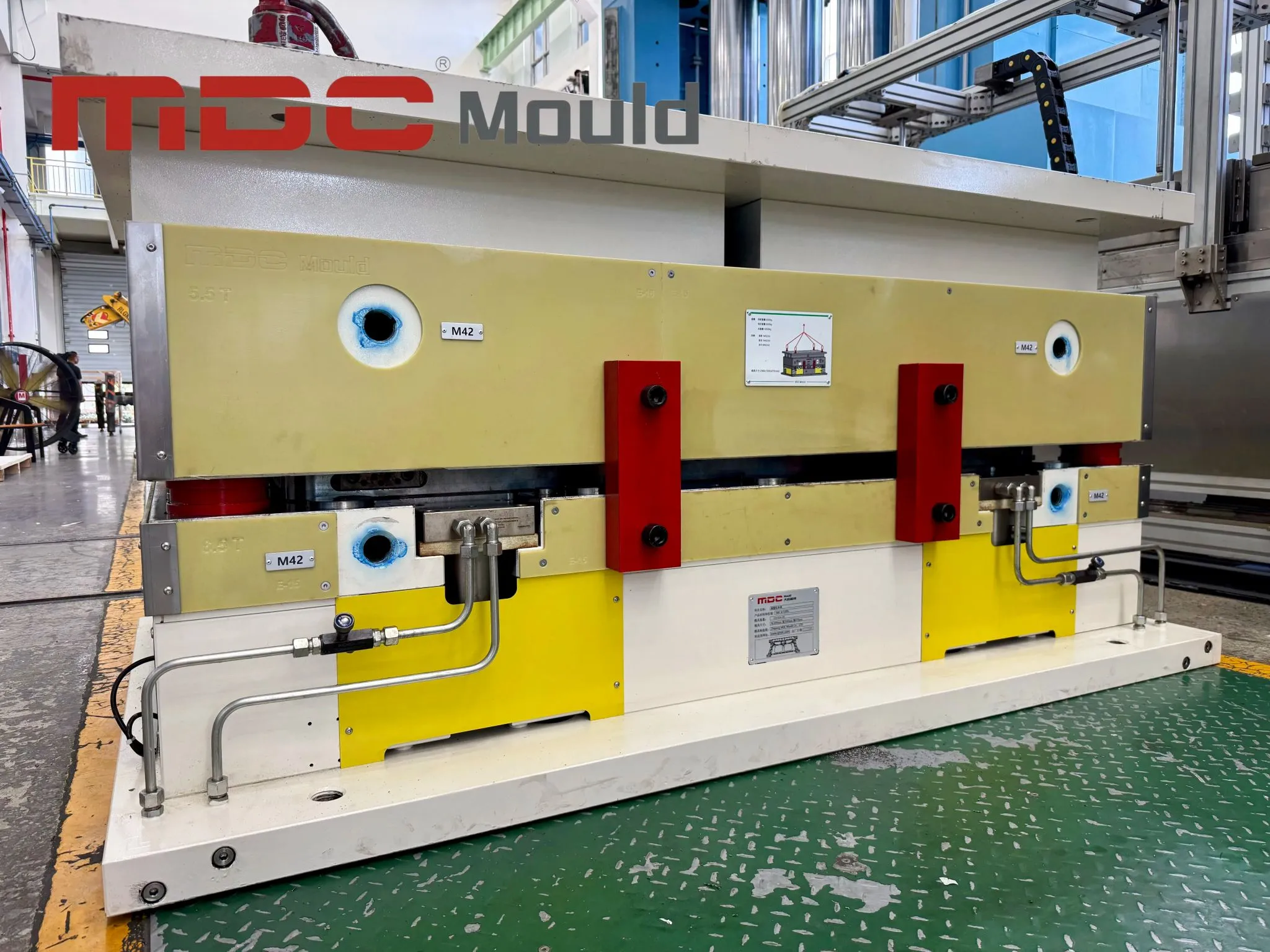

5. Implications for MDC Mould and the composite tooling industry

For a composite tooling specialist like MDC Mould, DMLS represents a strategic technology to complement existing CNC and EDM capabilities. Specific opportunities include:

- Rapid prototype compression molds for SMC and BMC trials.

- Optimized molds with conformal cooling to reduce curing cycle time and improve part consistency.

- Customized lightweight tooling for large composite parts where handling and transport costs are significant.

- Hybrid production lines in which DMLS cores are enclosed by conventionally manufactured cladding to balance cost and performance.

Adopting DMLS helps MDC strengthen its service offering for automotive SMC body panels, EV enclosures, structural composite parts, and specialized thermoforming tooling.

6. Recommended next steps for industrial adoption

- Run pilot projects combining DMLS-produced cores with CNC-finished faces for representative SMC mold designs.

- Perform full-cycle mold trials to validate wear resistance, demolding behavior, and part quality.

- Establish an internal AM design-for-manufacture (DfAM) guideline focused on lattice sizing, channel diameter, and post-processing sequences.

- Engage material suppliers to certify tool-steel powders specific to SMC process abrasion and thermal cycles.

Conclusion

This computational study demonstrates that DMLS is a technically viable option for modern compression mold manufacturing. When combined with conformal cooling and hybrid finishing strategies, DMLS molds can meet the strict structural and thermal demands of SMC compression processes while delivering substantial material savings and enhanced design freedom. For SMC mold and composite tooling providers, integrating DMLS into the manufacturing mix will open new possibilities for performance, sustainability, and rapid iteration.

Contact MDC Mould to learn how we integrate additive manufacturing with precision CNC finishing for next-generation compression molds: Contact us.

Core keywords: DMLS, compression mold, SMC mold, composite tooling, metal additive manufacturing, honeycomb mold, conformal cooling.