Comprehensive professional insight into how polymer composite additive manufacturing (large-format) is reshaping infrastructure — and how MDC Mould’s composite tooling and processing expertise accelerates industrial adoption.

1. Material Systems and Printing Technologies

1.1 Thermoplastic and Thermoset Matrix Systems

Polymer composites used in additive manufacturing generally fall into two broad categories: thermoplastic and thermoset systems. Each class delivers distinct advantages for civil engineering applications.

Thermoplastic Composites

- PLA — biodegradable and sustainable; suitable for low-temperature, temporary or recyclable applications. Performance can be enhanced with fiber or nanoparticle reinforcement.

- ABS — higher impact resistance and better outdoor performance than PLA; commonly used for durable printed architectural components.

- High-performance thermoplastics (PEEK, ULTEM) — for demanding, high-temperature or chemically aggressive environments.

- Recycled thermoplastics (rPET) — reduce lifecycle carbon footprint, though require material control to limit molecular degradation.

Thermoset Composites

SLA/DLP and thermoset-based printing deliver excellent dimensional accuracy and thermal stability, but their cross-linked chemistry creates recyclability challenges for large-scale civil use.

1.2 Fiber-Reinforced Composite Systems

Reinforcements determine structural performance:

- GFRP — fatigue resistance, cost-effective for large components (façade modules, pedestrian bridges).

- CFRP — extremely high strength-to-weight; ideal for precision structural parts and retrofits.

- Natural fibers — (bamboo, flax, hemp) promising for sustainability but need surface treatments for moisture/UV resistance.

- Particle fillers — SiO₂, Al₂O₃ to increase stiffness, thermal performance or wear resistance.

1.3 Large-Scale Additive Manufacturing Technologies

Key printing technologies used in civil engineering:

Extrusion-Based 3D Printing (E3DP)

Most common for large geometries — balanced between scale and speed; supports composite filaments and pellet-fed systems.

Binder Jetting

Enables powder-based composites and hybrid mixtures with low thermal deformation and good surface finish.

Robotic Large-Format Additive Manufacturing (RLFAM)

Multi-axis robotic deposition allows support-free printing, complex geometry, and continuous fiber reinforcement — perfect for bespoke bridge components, stiffeners, and façade systems.

2. Global Case Studies: From Bridges to Buildings

Practical projects worldwide demonstrate how composite 3D printing is applied at scale.

2.1 Bridge Engineering

- Rotterdam (Netherlands) — 6.5 m pedestrian bridge printed from GFR-PET, reduced lifecycle carbon by ~50% (example of environmental and durability benefits).

- Limburg Pedestrian Bridge — validated cyclic performance for pedestrian loads, showing predictable fatigue behaviour in GFRP structures.

- Liuyun Bridge (China) — 17.5 m bridge printed from ASA-3012 composite in 35 days; illustrates speed and logistical advantages for medium-span pedestrian infrastructure.

2.2 Building & Modular Construction

- BioHome 3D (USA) — bio-fiber + bio-resin printed modules that are recyclable and rapidly deployed.

- Jindi Modular Housing (Australia) — recycled plastics core + cementitious outer coating for improved fire performance.

- Azure Tiny Homes (USA) — small modules printed in 24–48 hours using recycled plastic feedstock at scale.

2.3 Structural Strengthening & Seismic Applications

Examples include continuous carbon-fiber printed grids and CFRP/PLA retrofits that increase energy dissipation and shear stiffness—offering promising strategies for earthquake-resistant upgrades and fast repair works.

3. Key Technical Challenges

Despite strong advantages, several engineering and industrial hurdles must be overcome for mainstream civil adoption:

3.1 Mechanical Anisotropy

Layered deposition creates directional properties—interlayer bonding is typically weaker than in-plane strength, necessitating design accommodations, fiber orientation control, and post-processing consolidation.

3.2 Durability & Environmental Resistance

- UV ageing and photodegradation

- Moisture uptake in natural fiber composites

- Fire resistance and compliance with building codes

3.3 Large-Scale Manufacturing Bottlenecks

Production speed, material cost, and equipment footprint remain obstacles. Example: a 5,800 kg printed bridge may require multiple weeks of continuous operation.

3.4 Standards & Certification

Industry standards, testing protocols and life-cycle performance databases are still evolving—this slows structural certification and insurance acceptance for critical infrastructure.

3.5 Recycling & End-of-Life Management

Thermoset matrices and fiber-reinforced composites lack mature closed-loop recycling pathways—an active research and industrial priority.

4. Future Directions and Opportunities

4.1 Process Optimization

Multi-axis deposition, in-situ consolidation and hybrid manufacturing that combine additive deposition with CNC finishing will improve accuracy and structural integrity.

4.2 Smart & Functional Materials

Embedding sensors, self-healing chemistries, conductive pathways and thermal-functional fillers will enable intelligent infrastructure systems and condition-based maintenance.

4.3 Sustainable Material Development

R&D focus includes bio-based polymers, improved recycled PET composites and treated natural fibers that lower environmental impact while meeting performance targets.

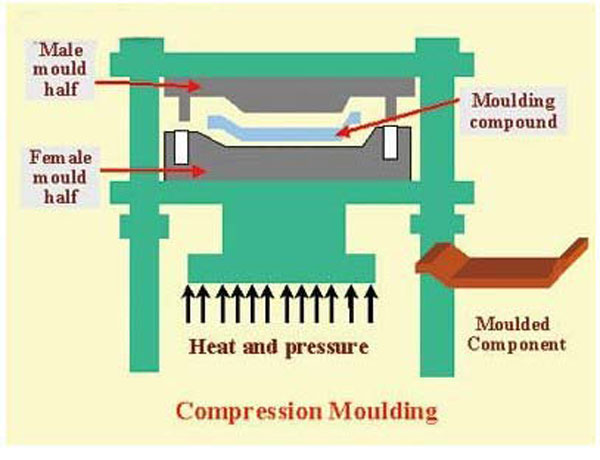

4.4 High-Performance Composite Tooling

Large printed components will increasingly rely on high-quality tooling and forming systems for prototype validation, hybrid cast–printed assemblies, and repeatable production. MDC’s SMC/BMC tooling, FRP moulds and precision forming solutions provide essential capabilities for scale-up.

4.5 Standardization & Policy Support

Development of structural design codes, durability databases and sustainability assessment frameworks will accelerate industrial adoption and risk acceptance.

5. How MDC Mould Supports Composite 3D Printing Adoption

MDC Mould (Zhejiang MDC Mould Co., Ltd.) sits at the intersection of advanced composite tooling and large-scale composite manufacturing. Below are ways MDC accelerates adoption:

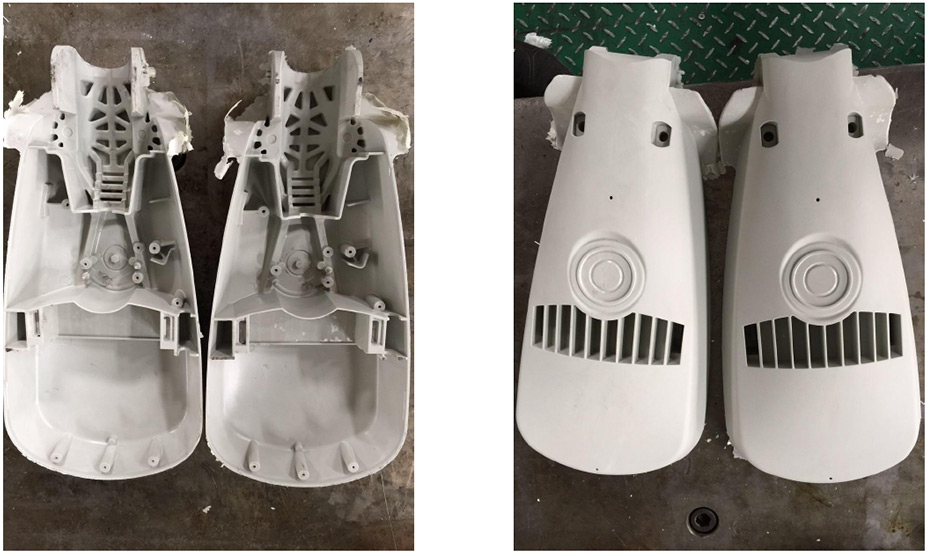

- Precision Prototype Tooling — SMC/BMC and FRP moulds for validation of printed geometries and hybrid cast–printed joints.

- Surface & Dimensional Finishing — post-print forming and high-accuracy tooling that enable modular façade systems and architectural finishes.

- Vacuum & Consolidation Solutions — vacuum systems and in-situ consolidation fixtures to improve interlayer bonding and composite density for load-bearing parts.

- Material Partnering — collaboration with filament, pellet and prepreg suppliers to qualify composite feedstocks for structural use.

- Testing & Certification Support — prototype testing, fatigue evaluation and long-term performance campaigns required by code bodies and clients.

- Hybrid Manufacturing Integration — combining large-format additive manufacturing with MDC’s subtractive tooling and finishing to deliver ready-to-install components.

For project inquiries — prototype tooling, pilot production, or hybrid cast–printed solutions — contact MDC Mould to discuss requirements and technical collaboration.

6. Conclusion

Polymer composite additive manufacturing is transitioning from research to impactful engineering practice across bridges, buildings and structural rehabilitation. While challenges in anisotropy, durability and standards remain, the combined progress in materials, processes and tooling creates a clear pathway toward scalable, sustainable infrastructure solutions.

MDC Mould—by providing high-performance composite tooling, vacuum/consolidation systems, and finishing services—plays a strategic role in enabling reliable, repeatable production for large-format composite structures. Partnering with tooling specialists reduces technical risk, shortens validation cycles and helps bring composite-printed infrastructure into mainstream engineering.